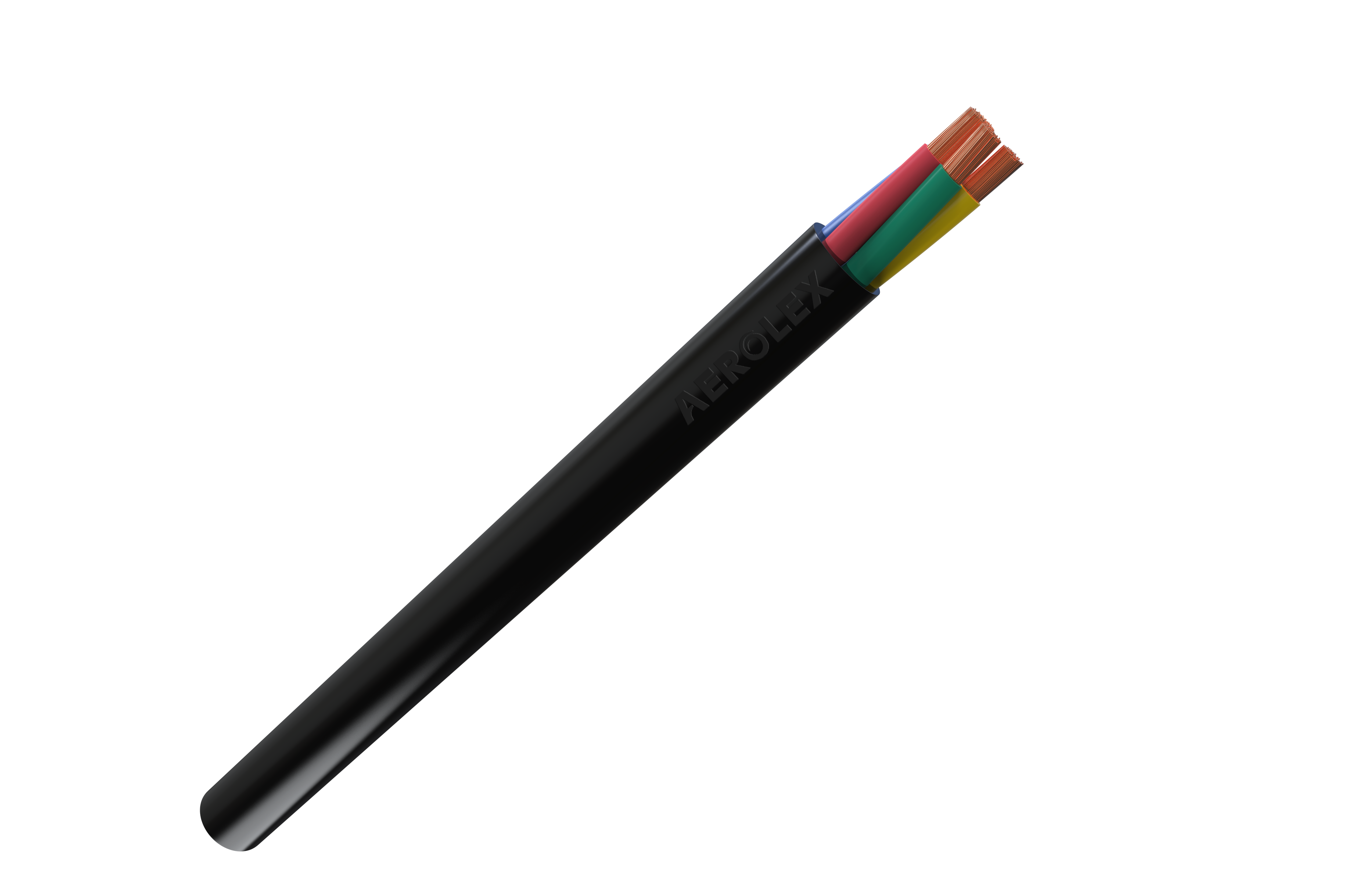

One stop solutions for Submersible Pump Cables

High purity electrolytic grade bright annealed flexible bunched bare, copper conductor according to international standards like IS 8130, BS 6360, IEC 228 & VDE 0295

Specially developed dielectric grade PVC Compound impervious to water, oils, grease etc.

Sheathing by High abrasion resistant tough & flexible PVC Compound

IS 694, BS 6500, IEC 60227, CEI 20-20, VDE 0281, SABS 1574, AS 3191, AS/NZS 5000.1, HD 21.1, NF C 32-201, French Standard 32-102-16

450/ 750 V, 600/ 1000 V, 650/1100 V

3000 V

-150C to 700C

| Core colors | (For Asian, African Markets) | (For European Markets) |

| 3 core | Red ,Yellow, Blue | Black, Blue, Brown |

| 4 core | Red ,Yellow, Blue, Green | Black, Blue, Brown, Green |

| Sheath color: | Choice of Black or Blue | Choice of Black or Blue |

|

|

|

|

|

| Area (nom) sq.mm |

No./size of wire no./mm |

Insulation thickness (nom.) mm |

Sheath thickness (nom.) mm |

Overall dimensions (approx.) Mm |

Conductor resistance at 200C ohm /km |

Current carrying capacity at 400C amps. |

| 3 x 1.5 | 22/.3 | 0.6 | 1.6 | 9.7 | 12.1 | 14 |

| 3 x 2.5 | 36/.3 | 0.7 | 1.6 | 10.7 | 7.41 | 18 |

| 3 x 4 | 56/.3 | 0.8 | 1.8 | 12.8 | 4.95 | 26 |

| 3 x 6 | 84/.3 | 0.8 | 1.8 | 14.4 | 3.3 | 31 |

| 3 x 10 | 140/.3 | 1 | 1.8 | 17.4 | 1.91 | 42 |

| 3 x 16 | 226/.3 | 1 | 2 | 21.2 | 1.21 | 57 |

| 3 x 25 | 354/.3 | 1.2 | 2.4 | 25.4 | 0.78 | 72 |

| 3 x 35 | 495/.3 | 1.2 | 2.6 | 29.1 | 0.554 | 90 |

| 3 x 50 | 703/.3 | 1.4 | 3.1 | 33.5 | 0.386 | 115 |

| 3 x 70 | 360/.5 | 1.4 | 3.1 | 39.1 | 0.272 | 143 |

| 3 x 95 | 475/.3 | 1.6 | 3.5 | 45.2 | 0.206 | 165 |

| Area (nom) sq.mm |

No./size of wire no./mm |

Insulation thickness (nom.) mm |

Sheath thickness (nom.) mm |

Overall dimensions (approx.) Mm |

Conductor resistance at 200C ohm /km |

Current carrying capacity at 400C amps. |

| 4 x 1.5 | 22/.3 | 0.6 | 1.6 | 10.5 | 12.1 | 14 |

| 4 x 2.5 | 36/.3 | 0.7 | 1.6 | 11.7 | 7.41 | 18 |

| 4 x 4 | 56/.3 | 0.8 | 1.8 | 14 | 4.95 | 26 |

| 4 x 6 | 84/.3 | 0.8 | 1.8 | 15.7 | 3.3 | 31 |

| 4 x 10 | 140/.3 | 1 | 1.8 | 19.1 | 1.91 | 42 |

| 4 x 16 | 226/.3 | 1 | 2 | 22.7 | 1.21 | 57 |

| 4 x 25 | 354/.3 | 1.2 | 2.6 | 29.4 | 0.78 | 72 |

| 4 x 35 | 495/.3 | 1.2 | 2.6 | 31.6 | 0.554 | 90 |

| 4 x 50 | 703/.3 | 1.4 | 3.1 | 37 | 0.386 | 115 |

| 4 x 70 | 360/.5 | 1.4 | 3.1 | 43.2 | 0.272 | 143 |

| 4 x 95 | 475/.3 | 1.6 | 3.5 | 50 | 0.206 | 165 |

Note:

Insulation thickness, Sheath thickness and overall dimensions are nominal values. The number of wires is approximate and strand diameter is nominal; they shall be such as to satisfy the requirements of conductor resistance as per IS 8130/1984, BS-6360, IEC-228 & VDE-0295.